Project Description

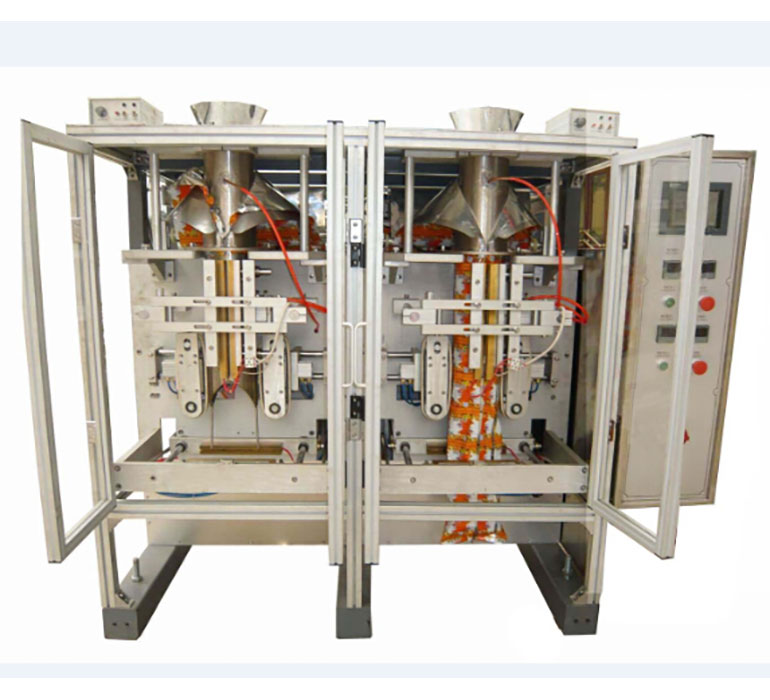

DOUBLE UNITS AUTOMATIC PACKAGING MACHINE

This series machines are usually packaging for more than 1000 ml bags.

INTRODUCTION

DXD-2500 (Our patent product)

This double units automatic filling and packaging machine is featured with one control system achieving two machine output. It is usually used for packaging bigger bag with more than 1000ml materials. It is widely used in food, phamecuetical and Chemical products, like granular materials like rice, salt,sugar,candy, nuts, puffed good, dry fruits and so on. It can also be made for packaging for powder, like milk powder, protein, wheat flour and so on. Furthermore, it can also be made for packaging for free flowing liquid or viscous liquid, like sauce, alcohol, jam,honey,Ketch-up and so on.

The display control screen has two languages, English and Chinese, which can be switched easily. The screen shows all information like running speed, trouble state, counting and production state. With Alternating Current servo motor, the film pulling process is stable, accurate, free from dust and lubricating. The stainless body makes sure it can work stable and good for food packaging. The control system is very smart and easy to operate. You only need to set the length of bag and filling amount. The control system will automatically match your parameters to the best optimization. Therefore it will achieve its best packaging speed.

In the course of production, Parameters can be adjusted without stopping machine. It adopts high accurate temperature controller to keep stable hot sealing temperature. It has automatic mistake alerting, such as materials got cut, safe switch on, film pulling not straight or film used up and ect.

WHERE WE HAVE IMPOVED?

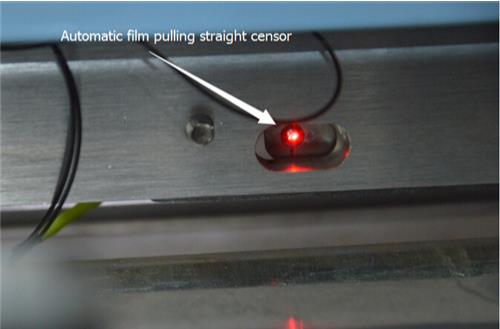

The automatic film pulling straight censor can detect the movement of film pulling. Once the pulling is not straight, the censor will “tell” the information to the relevant Motor to make it straight. In this way, the machine can work efficiently and saving films.

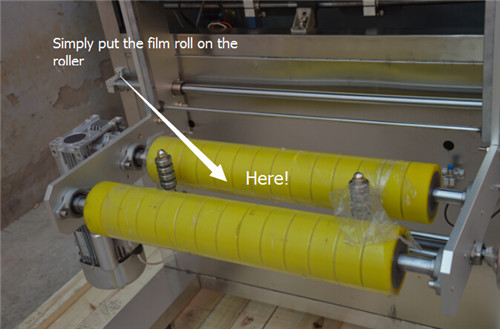

The old type film sending part has a reel. you have to take down the reel to load new film roll when finished every time. It takes time to change over. With the new type “sitting roller”, you just need to simply put the film roll on the roller, saving much time and easy.

COMPONENTS WE PROVIDE

Please choose the components you need

VIDEOS OF OUR MACHINES

GET IN TOUCH

Please fill out the form below. We’ll respond as soon as possible.