Project Description

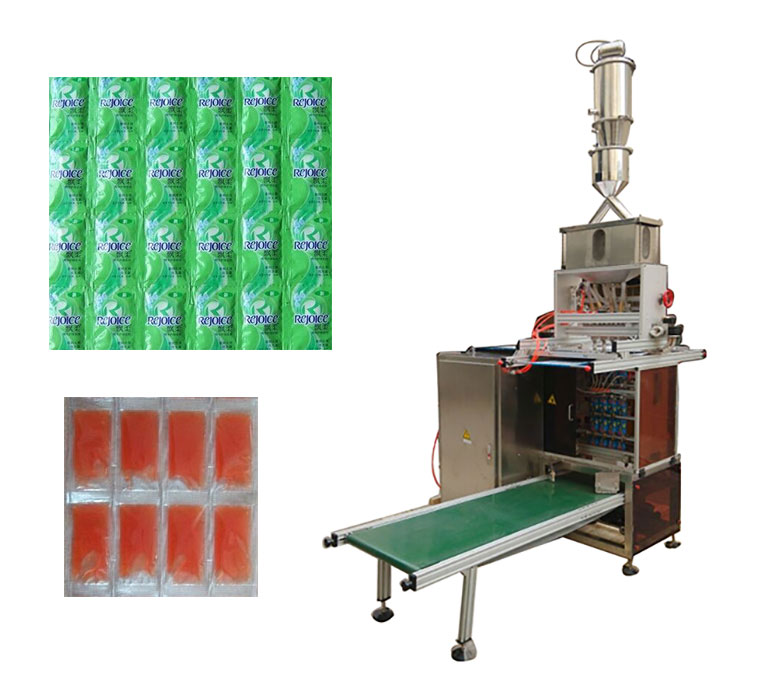

MULTI-LANE PACKAGING MACHINE (4 sizes sealing)

This series of machines are usually packaging for 4 sizes sealing.

FEATURES

We adhere to the word ” Perfection has on end!”

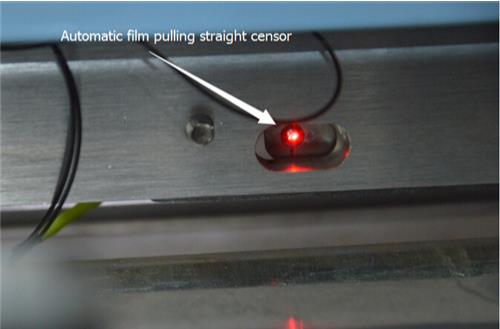

1, The film pulling part has automatic straight pulling censor, which could ensure the film

running in a straight way.

2, Friendly interface touchable control system

3, Smart temperature control

4, Automatic error alert

5, Measuring,bags making,filling,sealing counting, all in one.

WHERE WE HAVE IMPOVED?

The automatic film pulling straight censor can detect the movement of film pulling. Once the pulling is not straight, the censor will “tell” the information to the relevant Motor to make it straight. In this way, the machine can work efficiently and saving films.

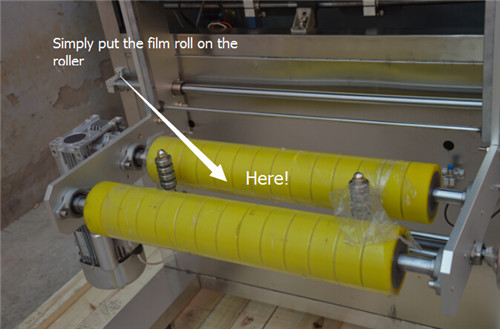

The old type film sending part has a reel. you have to take down the reel to load new film roll when finished every time. It takes time to change over. With the new type “sitting roller”, you just need to simply put the film roll on the roller, saving much time and easy.

SPECIFICATIONS FOR DXD-150

| Bag size (mm) |

Maximum film width (mm) |

Packaging speed (bags/min) |

Volume (ml) |

Filling accuracy |

Shape of bag |

Power (v/Hz/kw) |

Air consumption (Mpa/min)(normal) |

Maximum row number |

Weight (kg) |

Dimension (mm) (L×W×H) |

| (L)50-150 | 1000 | Single-file 20-60 |

5-50 | ±2% | Four sides | 220/50/7 | 0.6/0.36m3 | 8 | 800 | 2270×1645×2110 |

VIDEOS OF OUR MACHINES

GET IN TOUCH

Please fill out the form below. We’ll respond as soon as possible.